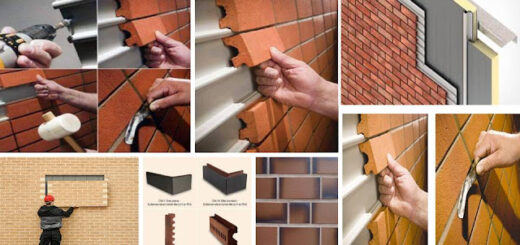

Interlocking Tiles and the Method of Implementation in Stages

Interlock tiles are a type of tile composed of chemically treated concrete. It is a concrete tile that is compacted without the use of cement mortar, but rather installed directly on top of compacted sand. The reason for this is its interlocking method and relying on its weight in its balance and non-movement. The tiles overlap each other so that they can be removed and reinstalled Install it when needed.

Among its most important features is that: Interlock tiles can withstand high pressures and loads of 250: 300 kg / cm2, and it is possible to carry out a load bearing force of 400: 450 kg / cm2. * The thickness of the piece ranges from 4-8 cm according to the request and according to the required pressure and use Its extreme abrasion resistance is less than 0.5mm with a water absorption rate of less than 4%, making it suitable for standard applications such as airports and gas stations.* Interlock tiles are made of washed sand with high cement proportions.

implementation methodFirst: The geometry and type of tiling required for the paving process are chosen, in order to determine the required tiles and their quantitySecond: The soil is scraped at a distance of 40 cm from the required level, that is, the site is cleaned well from any unclean materials such as stones or construction waste. Your blood coefficient is 97%, but if it is for times, then we replace the base-course layer with a layer of sand, which is coarse sand, in which the percentage of gravel does not exceed 10%. After leveling the natural land according to the required levels and inclinations, i.e. the budget is made for the floor and the inclinations are determined with threadsTALTA: The bezel surrounding the interlock surface or area is made according to the plan or description, where the bezel specified for the interlock surface can be made of rubble, refractory bricks, bricks, or concrete. The burial layer (sand layer below the tiles) is placed within the limits of 5:7 cm, and the sand must be red, clean, free of stones, and it is sprayed with water well and spread out, then it is compacted and leveled well by means of an aluminum beam or stump to obtain a flat surface under the tilesFourth: The water balance is used to ensure a good flow of water, making inclinations towards the street, after that the tiles are installed directly on the burial, and the boilers (parts of the tiles) are installed, and after the completion of the tiling, clean sand is sprinkled.Finally, the surface that has been tiled is cleaned.

Recent Comments